About Us.

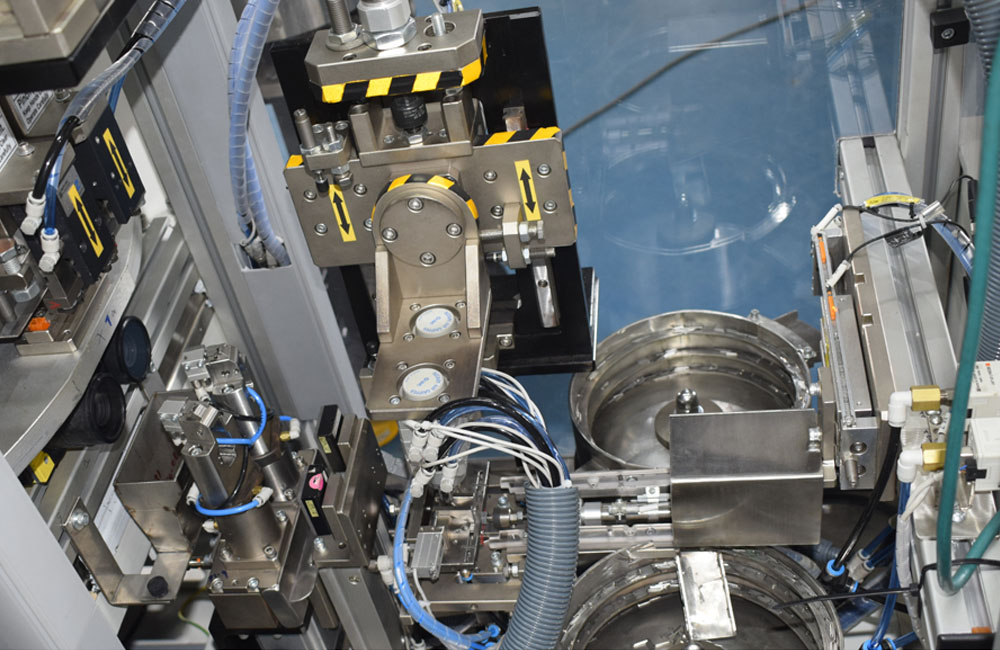

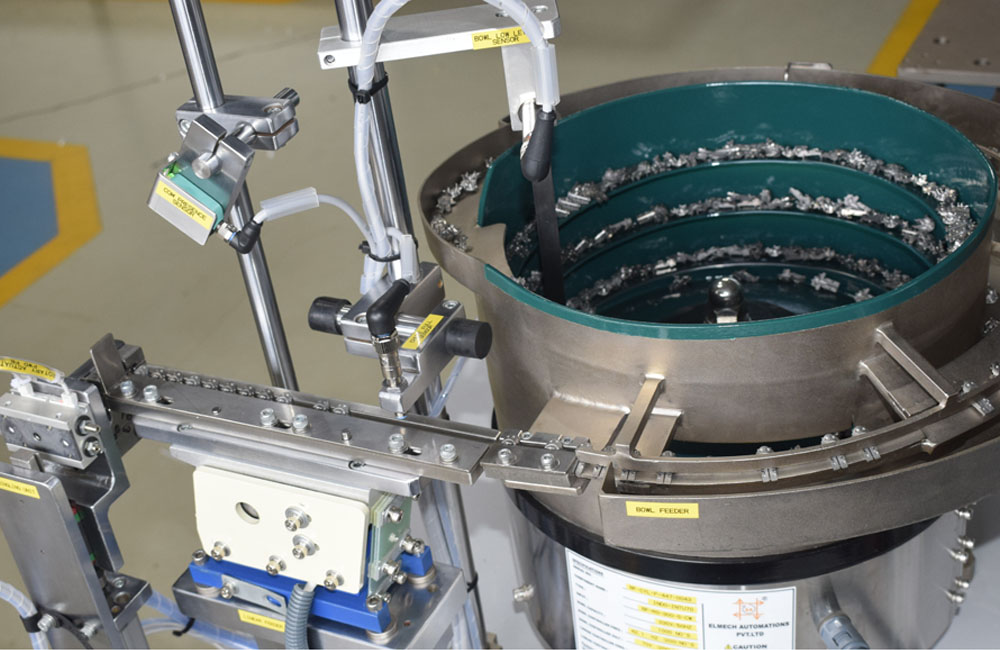

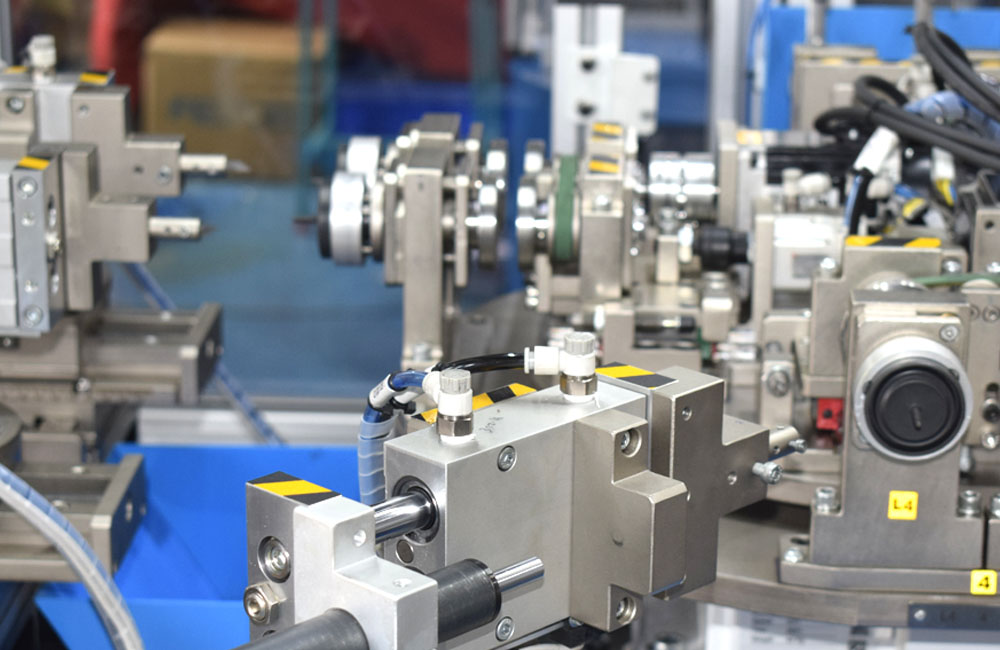

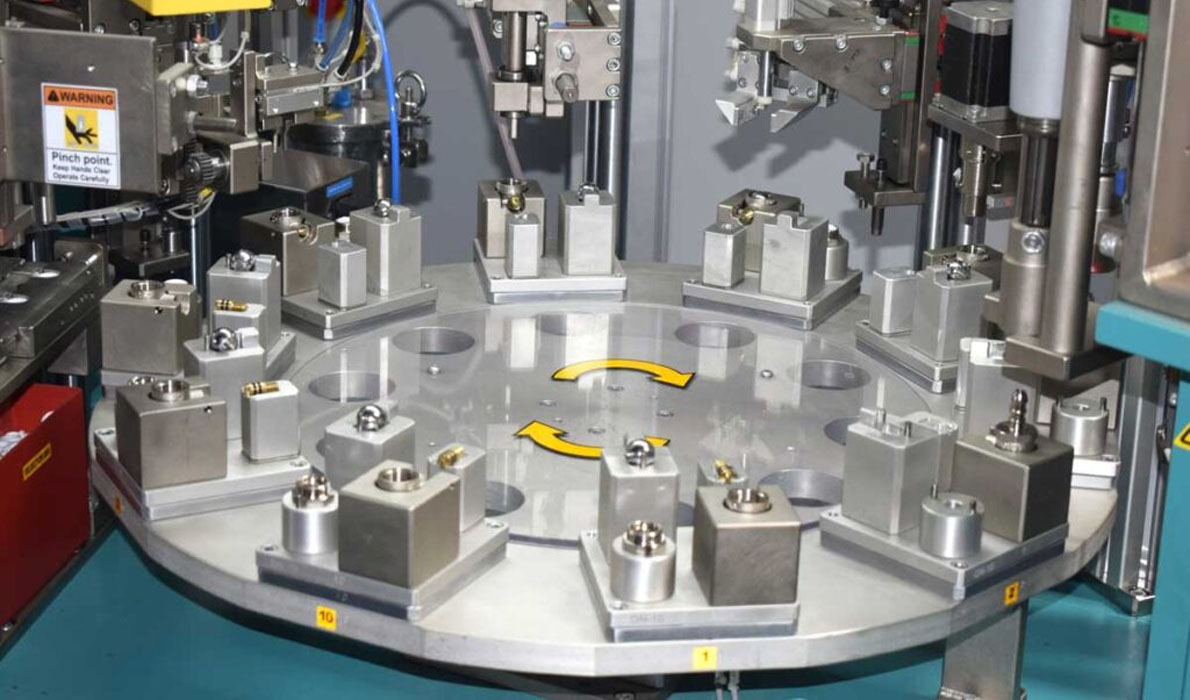

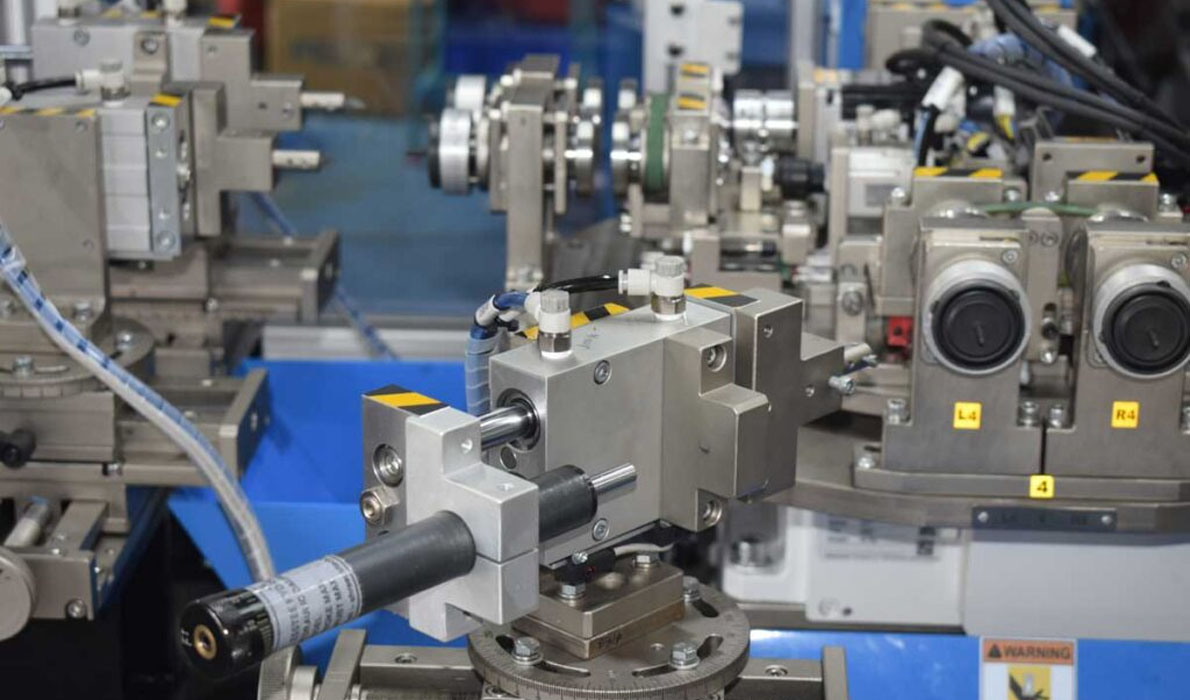

MOLDBETTER Automations is a System Integrator and Automation solutions provider company, serving wide range of industries such as Automotive, Electronics, Pharma, Water taps and faucets etc,. MOLDBETTER Automation has evolved across the years to emerge as the trusted supplier of efficient assembly and other automation solutions that empower our clients and their businesses. MOLDBETTER excels in catering to a wide variety of industrial automation needs in the areas of Process automation, Machine building, Feeding solutions.

We Automate Production By Feeding, Assembling, Tesing.Explore project0102

We Automate Production By Feeding, Assembling, Tesing.Explore project0102 We Automate Production By Feeding, Assembling, TesingExplore project0203

We Automate Production By Feeding, Assembling, TesingExplore project0203 We Automate Production By Feeding, Assembling, TesingExplore project0301

We Automate Production By Feeding, Assembling, TesingExplore project0301